Layout the Plan

Acquire Material

>Nail up Boxes

Drill the Framing

Pull Wire

Make up Connections

Inspection

The Rough In Step 3 Nail Up Boxes

Mount electrical boxes, housings and panels to the stud and joist framing before sheet rock is installed.

Using a hammer as a measuring stick to set the height of a

single gang, nail on box for a receptacle.

After marking locations in the layout and acquiring your supplies the next step is to mount the electrical boxes and housings to the wall studs and ceiling joists. The supplies are distributed around the house according to the script and then mounted in place. Mounting is done with nails, screws and staples. Nails come attached to most boxes and a few models of recessed can lights. Screws are enclosed with some items like ceiling fan boxes. Staples, that are used for wires, come in handy for mounting other items.

Most of the 'Nailing Up' step is simple enough to be done by an inexperienced electrician. Nailing up recessed can lights in the 4 corners of a rectangular shaped bedroom is real easy but nailing them up in odd shaped rooms or in ceilings with complex 45º joist framing can be more challenging.

Most of the 'Nailing Up' step is simple enough to be done by an inexperienced electrician. Nailing up recessed can lights in the 4 corners of a rectangular shaped bedroom is real easy but nailing them up in odd shaped rooms or in ceilings with complex 45º joist framing can be more challenging.

Distribute the supplies.

Electricians begin the Nailing up step by distributing supplies around the house. Someone will grab an armful of single gang nail on boxes and start laying them down on the floor, one at a time, under the marks that indicate where these single gangs will be nailed up. Someone else will distribute the 2 and 3 gang boxes.

By reading the layout script, the electricians know which boxes go where. If the stud is marked "S" for switch, it will need a single gang nail on box for a single switch. Another single gang is used for receptacles marked on the walls with an "R" (see the hammer photo) If the mark reads SS it will need a 2 gang box for 2 switches. SSS needs a 3 gang box. So does S1 S3 S4 , where there will also be 3 switches: one single pole (S1), one three way (S3) and one four way switch (S4)

Here is a picture of a single gang, a 2 gang and a 4/0 nail on box,

By reading the layout script, the electricians know which boxes go where. If the stud is marked "S" for switch, it will need a single gang nail on box for a single switch. Another single gang is used for receptacles marked on the walls with an "R" (see the hammer photo) If the mark reads SS it will need a 2 gang box for 2 switches. SSS needs a 3 gang box. So does S1 S3 S4 , where there will also be 3 switches: one single pole (S1), one three way (S3) and one four way switch (S4)

Here is a picture of a single gang, a 2 gang and a 4/0 nail on box,

Single gang nail on boxes come in different depths normally 18, 20 and 22 cubic inches. Your company might use 20 cubic inch boxes for all single gang needs. Other companies might use a deep 22 cubic inch single gang for GFI receptacle locations. There is not much visible difference between a 20 and 22 cubic inch box. They should have the size labeled on or inside the box. You will be creating problems if you mount a shallow 18 cubic inch box in a location that requires a special deep box.

If the work area is somewhat clean then items for the ceiling can be set on the floor below their mounting location. If the area is cluttered and busy, set ceiling items by the wall switch that will control them. The script for a standard ceiling fixture looks like a circle with a cross through it, ⊕ This is where a 4/0 (pronounced four, oh) light box would be set. The script for a standard recessed can light looks like a circle with a letter "C" in it. ©

Recessed can lights are usually sold 6 to a case. These cases are distributed around the house to rooms where they will be needed. If a room needs 6 recessed can lights, then a case can be set by the switch box in that room. Can lights that are not in a case need to be set close to walls where workers won't trip over them or have them tangle up in their extension cords. Some houses have only one style of can light housing. This makes it easy because everywhere the script locates a can it will be the same style. Other houses have a variety housing sizes and styles. You will have to know how the script identifies different styles of recessed can lights.

Here is a picture of a standard recessed can light,

Distributing light boxes is more difficult than the rest. Light boxes require knowing where center will be before you can decide which style of box to use.

If the center is exactly on a ceiling joist then a pancake box is used.

If the center is 2 inches off the joist a 4/0 nail on box is used.

If the center is beyond 2 inches from the joist a bar hanger box is used.

Heavy lights in dining rooms and entryways require a heavy duty metal light box.

Ceiling fans require a special fan rated box.

If the work area is somewhat clean then items for the ceiling can be set on the floor below their mounting location. If the area is cluttered and busy, set ceiling items by the wall switch that will control them. The script for a standard ceiling fixture looks like a circle with a cross through it, ⊕ This is where a 4/0 (pronounced four, oh) light box would be set. The script for a standard recessed can light looks like a circle with a letter "C" in it. ©

Recessed can lights are usually sold 6 to a case. These cases are distributed around the house to rooms where they will be needed. If a room needs 6 recessed can lights, then a case can be set by the switch box in that room. Can lights that are not in a case need to be set close to walls where workers won't trip over them or have them tangle up in their extension cords. Some houses have only one style of can light housing. This makes it easy because everywhere the script locates a can it will be the same style. Other houses have a variety housing sizes and styles. You will have to know how the script identifies different styles of recessed can lights.

Here is a picture of a standard recessed can light,

If attic insulation will be placed around your can light be sure your can is rated "IC" for insulation contact. Non IC cans are used when there is another floor above and no insulation around the can.

In cold northern climates, special boxes are used for insulated walls and ceilings. These boxes have an additional weather gasket attached to them. So an "R" on a wall between bedrooms would get a standard one gang nail on box but an "R" on a the bedroom wall that is shared with the outside will get a special one gang nail on box with the insulating gasket. Also a standard 4/0 light box is used when the space above the light is a heated second floor room but a special 4/0 box with a gasket when the space above is an insulated attic.

The Nailing up begins after a good amount of boxes and can lights are distributed around the house.

✦ "Nailing Up" Key Points ✦

✦ Know the "height method" and "height measurement"

✦ Know the depth of the finished wall or ceiling.

✦ Nail the box level, flush and plumb.

✦ Close boxes have to be exact.

Know the "height method" and "height measurement"

Electricians use different height methods for mounting device (switch and receptacle) boxes. Be sure to use the same method as those you are working with. Some measure, mark and nail the box with the mark even with the bottom of the box, others set the mark even with the top of the box and yet others nail the box with the mark in the center. It is best to mount rectangular device boxes with the mark on the bottom of the box and round boxes with the mark at the center of the box. Use 44" to the bottom of switches, kitchen counter outlets and garages. But, follow your companies methods.

Know the depth of the finished wall or ceiling.

You want the box to be flush, not sticking out past the sheet rocked wall surface and you also don't want the box sunk deep into a wall. 90 % of houses use 1/2 inch sheet rock which means your box can stick out according to the depth marks indicated on the side of your box. Fire walls, between a duplex or other apartments, might have a double layer of 1/2 or 5/8 inch sheet rock. Sometimes, 1" thick brick is used on the inside walls. Check the prints or ask your supervisor for the correct depth.

Nail the box level, flush and plumb.

A 4 gang switch box looks pretty bad when it is not level. Loosen or sink one of the 2 nails until the box is level. A properly nailed box can still stick out of the wall on one side if the stud is twisted. Try hitting the stud at the bottom until your box looks flush (it will not stick out when sheet rock is installed) A plastic switch box can twist and distort. The top and bottom can be level but, because of a twist in the middle, the top screw hole will be out of plumb with the bottom screw hole making it hard to mount the device. Loosen or sink one of the 2 nails until the box screw holes are plumb.

Close boxes have to be exact.

Boxes that are very close together need to be nailed up at more exact heights. Take a little more time to get the exact height when 2 separate boxes are on either side of the same stud at the same heights. Especially on a kitchen counter.

✦ Can Light Mounting Key Points ✦

✦ Find the center mark

✦ Orient the junction box.

✦ Mount to one joist at a time.

✦ Lock into positionFind the center mark

Measure off the wall, that the ceiling joists are heading to, and mark your center on the ceiling joist with a marker. On complex ceiling framing, attach a string to the ceiling, parallel with the wall, to help you find your centers.

Orient the junction box.

Recessed can lights come with an attached wiring compartment or junction box. Think about the best placement of the junction box before mounting a can light. If you know your wires are coming from the right then spin the can light around until the junction box is facing the right.

Mount to one joist at a time

Place the can on the center mark and grab the can and the joist with one hand while nailing the 2 brackets with your other hand. Then slide the brackets over to the other joist and nail in place.

Lock into exact position

The can should be able to slide on the brackets from one joist to the other. Measure off the other wall and mark your center on your brackets. Slide the can until it is centered on your mark and lock the can into position. Can lights are locked into position by tightening a bracket screw or by using your lineman pliers to fold a piece of metal that the bracket passes through.

The Rough In

Layout the Plan

Acquire Material

Nail up Boxes

>Drill the Framing

Pull Wire

Make up Connections

Inspection

The Rough In Step 4 Drill the Framing

Creating a pathway, through the framing, for all the wiring throughout the house.

Introduction to Drilling

You are ready to begin drilling when the electrical Layout is complete and all the boxes and housings have been Nailed up according to your script markings on the walls and floor. Drilling too soon might cause you to waste time and energy drilling extra, unnecessary holes. With everything nailed in place you can see the box to box wiring path where your holes will need to be drilled

The basic idea of the Drilling step is to provide a pathway for all the wiring that you will be running throughout the house. Electrical wires, low voltage door bell wires and, when required, phone and TV wires. For example you will drill a line of holes along the length of a wall from receptacle box to receptacles box, and a hole above a switch box to run a cable up to a light. The goal is to drill as many holes as possible without drilling any unnecessary holes. When it is time to start pulling wire you want to be able to pull the wire through the holes from box to box without having to stop to drill a missed hole.

The more holes (necessary holes) that are drilled before pulling wire, the less risk there is of accidentally drilling through a wire. There might be 3 electricians pulling wire and only 1 company drill. If only ½ the holes are drilled throughout the house then 2 of these 3 workers will be waiting for the drill. They will have to stop pulling wire every time they discover another hole not drilled. All of this will slow down productivity. To avoid this delay someone has to drill and keep drilling until all the holes needed are drilled out.

Some drilling requires more advanced knowledge of the job site's circuit and wire pulling plan. If you know the circuit plan then you will know which way to drill; up, down, left or right.

Here is a list of good places for a rookie to begin drilling because they are so common;

>The path connecting receptacles and switches in a bedrooms.

>Above a switch box

>Above a vanity receptacle.

>Above a phone or cable TV box

>Above garage receptacles and garage door eyes.

Safety

✘ The drill's side handle can spin around and hit you in the head, try to hold the drill at a distance or rest the handle against a stud. Drilling without the secondary, detachable side handle can injure your wrists.

✘ Long hair, coat hood strings or necklaces can get caught in the spinning drill bit and cause injury.

✘ Wear safety glasses, drilling up and into an unseen nail can cause hot metal shavings to fall into your eyes.

✘ Long hair, coat hood strings or necklaces can get caught in the spinning drill bit and cause injury.

✘ Wear safety glasses, drilling up and into an unseen nail can cause hot metal shavings to fall into your eyes.

It is recommended that you use a ⅞ inch wide by 17 inch long bit with a double cutting edge. The bit needs to be long enough to drill through 6 to 8 framing studs that are nailed together.

General drilling techniques

Drilling across a wall

Keep your holes in the center of the stud so that a sheet rock screw can't damage the wire running through it. The code requires a nail plate to be nail on the stud by your wire if the hole is too close to the nailing surface. Try to drill your holes level with each other, the same height off the floor. It doesn't have to be exact, just somewhat level. Don't drill so low that your holes will be at the height where the base trim will be nailed. Avoid the mounting screws of upper and lower kitchen cabinets by keeping your holes within the back splash area of the kitchen counter.

When you pull your wire around a bedroom, from receptacle to receptacle, the wire will go up the stud from the box to your hole, thru your holes and back down to the next box. If your holes are a foot higher than necessary, you will be wasting a foot of wire to get up to your hole and another foot wasted going back down. 2 feet of wasted wire between 2 boxes with 50 more boxes to wire; 2x50=100 feet of wire wasted. Keep your holes within 8 inches above or below a line of boxes to save wire and make you a more productive and valued employee.

Drill through the soft spots

Avoid drilling through knots and nails. Knots are created from the branch of a tree and are common in framing lumber. They are made of very hard wood making it difficult to drill through. If you start a hole and you realize you are going real slow because of a knot, stop and start a new hole 2 or 3 inches away from the knot.

Avoid nails that you see and areas where you know nails are, like where a stud is nailed to a bottom plate. When you hear or feel your bit hitting a nail, stop drilling and start a new hole or you can try to remove the nail and then continue drilling. Unfortunately there are times when you just have to go through no matter what happens.

Protect the drill bit tip

Avoid hitting concrete or bricks with the tip of the drill bit. Sometimes brick or concrete lies just beyond a stud that you are drilling, especially in basements. Try to ease off on the drill so you don't bounce into these hard surfaces. Concrete will damage the threaded tip on the drill bit. The threaded tip helps to pull the drill bit into the wood. When it is damaged you will have to push really hard. It is easy to sharpen the cutting edge of a drill bit but fixing damaged threads on the pointed tip is very difficult.

Look before you drill

Look around to the back side of the wood before you drill through. You don't want to damage a plumbing pipe or wires hiding on the other side of the stud or joist. If you damage a plumbing pipe, be sure to tell your boss or the plumber. Most repairs are easy and cheap to do before the sheet rock is installed. If you don't tell someone, it might go unnoticed until the house is finished. Then when the water is turned on it will leak out and cause expensive damage.

Drilling up

Many wires are run up the wall, through the top plate and across the ceiling. For example a wall switch for a ceiling fan will have a wire run from the switch box up the wall and across the ceiling to the fan box. Holes need to be drilled through the top plate above switch box. Electrical panels will have many wires, called home runs, that will have to pass through several holes in the top plate. If your company will be pulling the phone wire and TV coax cable, a hole will be drilled above and/or below each phone and TV box.

When drilling up through the top plate the drill handle can spin around and hit you in the head, try to hold the drill at a distance or rest the handle against a stud.

> Start the bit very slowly into the wood to see how the handle will move as it spins clockwise.

> Allow the handle to slowly spin until it rests against a stud.

> Adjust your body and drill position to prepare for this spinning force and begin drilling.

Tall walls

An average worker will be able to reach and drill the top plate on an average wall using the standard 20 inch electricians drill bit. Walls exceeding 10 feet will require the use of a small ladder. The ladder will have to be carried around to all the locations that need a hole drilled up through the top plate. Using a 20 inch extension bit will allow a greater reach and make drilling faster by avoiding the need to haul a ladder around. The extension bit is inserted into the drill and the drill bit is inserted into the extension.

Drilling down

When drilling down, prepare to stop the moment you punch through so you don't hit something like a pipe or vent. Some houses have floors heated with specialized plastic hot water pipes attached to the bottom of the floor. It is hard to avoid hitting floor pipes. Try to drill slower and with easy pressure the moment your bit is about to break through the wood. If you know that floor heating crew is about to begin, get all your floor holes drilled quickly.

When drilling down it is common to end up stuck in a floor joist. You drill and drill and never seem to get through to the lower level because you are drilling through a 12 inch floor joist. When this happens, stop, pull the bit out and drill a new hole down at a double 45º angle. Meaning 45º off a plumb line and 45º off a north-south wall line (north-east is 45º from a north south line) If the wall is running north-south and the floor joists are running east-west, aim your drill bit at a 45º angle pointing northwest (or northeast, southwest etc..)

Drilling out

There are several wires that will have to extend to the exterior of the house. Outside wall lights, outside receptacles and air conditioner units are the most common places that holes will need to be drilled out. Sometimes the hole has to be in an exact location. For example, the hole for air conditioner wiring should be 2 feet directly above the unit's condensation lines. A disconnect box will be mounted where the wire sticks out. If the hole is drilled to the side instead of directly above the condensation lines, the disconnect box might end up behind the unit making it hard to access.

When the exterior is going to be bricked, your holes drilled out don't have to be in exact locations. There will be a space between the wall surface and the brick that allows your wire to reroute from the hole to the exact box location.

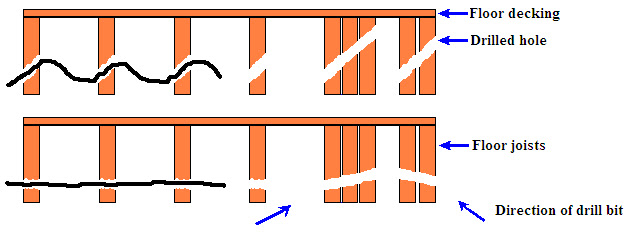

When drilling across the ceiling or second levels floor joists, keep your holes level.

The diagram at the top shows how hard it will be to pull a wire through the holes that were all drilled upward at a steep angle and all from left to right. The lower drawing shows correct drilling. Notice how the last hole was drilled from right to left, through the double joist, to meet with the hole that was drilled left to right through the triple joists.

For more informative posts and to learn about the best home inspection mobile al check out Trinity Home Inspections.

ReplyDelete